| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | HUABOND® |

| Model Number : | H-H121 |

| Certification : | ISO, TUV, BV, SGS |

| Payment Terms : | T/T, L/C |

| Supply Ability : | 150000m2/ Year |

Quick Details

Place of Origin: Changsha, China

Brand Name: HUABOND®

Model Number: H-H121

Core cell: 4.8-30mm

Usage: Indoor, Outdoor

Application: FurnitureDoorsDecoration materials..

Function: Anti-Static, Antibacterial, Fireproof, Mould Proof

Surface Treatment: Anodized, Brushed, Foil Decoration, Mirror

Color: Customer's Requirements

Material: Aluminum

Supply Ability: 150000 Square Meter/Square Meters per Month

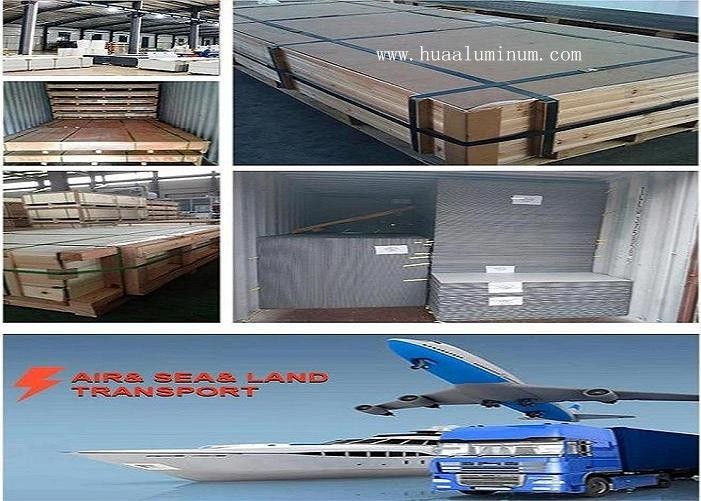

Packaging Details: Wooden pallet

Port: Guangzhou, China

Honeycomb Core Feature:

Aluminum honeycomb core as a new product, has been widely applied

in various fields. Our products market nationwide and exported to

all over the world have large. Widely used in various industries.

Decoration materials Aluminium honeycomb panel wall plywood,

Aluminium honeycomb composite ceiling, Aluminium honeycomb

anti-static flooring, Aluminium honeycomb composite partition

Aluminum honeycomb composite fire doors, Aluminum honeycomb

composite marble, etc.

Household appliances Air conditioning cold accelerant mesh,

Refrigerator deodorant, Heater lattice nets, Air purifier

ventilation bars, etc.

Lighting industry: Various light guide grating exhibition, the

traffic light, etc.

Transportation industry: Aluminum honeycomb composite of the train,

Train doors, partition, Aluminum honeycomb composite ship trim

panels, etc.

Furniture industry: All kinds of furniture of honeycomb composite

with moisture proof, moth-proofing, fire prevention function.

One of the primary reasons for utilizing aluminum honeycomb panels

is that they exhibit excellent strength-to-weight ratios compared

to traditional construction materials.

Strength

The ability to configure panels with different materials allows us

to create much stronger panels than one can achieve with solid

structures. The skill, however, is in analyzing all of the material

choices for meeting your specifications and then selecting those

that will provide the most functionality at the lowest cost.

Fire Resistance

Huabond uses a number of materials that are non-combustible and

self extinguishing. Most flammability ratings and building codes

can be easily met with some combination of materials.

Thermal Control

Most aluminum honeycomb panels have excellent insulation properties

simply due to the nature in which they are designed. Since both

honeycomb and foam cores trap air between the skins, they are

inherently insulating to some degree.

Sound Control

While we do not specialize in acoustical panels, we are happy to

incorporate any type of sound deadening specifications into the

composite panels that we design.

Impact Resistance

Impact resistance can be accounted for by adjusting the honeycomb

cell size, utilizing different core materials and skins, or adding

thickness to the surface material and/or core.

Moisture Resistance

All types of aluminum and plastic honeycomb cores can be used to

improve water and moisture resistance, but RFP surface materials

can also do the job for many applications.

Corrosion Resistance

Not only can we utilize different core and surface materials to

achieve resistance to weather and chemicals, but coatings can be

applied for added security.

Advantages of Aluminum Honeycomb Sheet

1. Energy saving, green material: Good thermal and sound insulation & sound insulation, fire resistance.

2. High wind load resistance: High strength & rigidness and stable

structure of honeycomb core.

3. Easy installation & low labor cost: Light weight

4. Good decoration: Excellent flatness & wide color selection.

New Design Core Aluminum Honeycomb Core Sandwich Panel

| Type | Aluminum honeycomb Panel for wall cladding |

| Pattern | Laminate / HPL / High Pressure Laminate Aluminum Honeycomb Panel |

| Aluminum Alloy | Solid Color/Metallic Color/ Wood Grain/ Marble Skin Look |

| Aluminum Panel Thickness | 10mm, 15mm,20mm,25mm |

| Adhesion Agent | Environmental Adhesive Film |

Product Parameter

| Project | Standard Specification and Parameter |

| Specification | Overall Thickness:10, 12, 15, 20, 25 mm |

| Width ≤ 1500 mm ( Other width can be negotiated) | |

| Length ≤ 10000 mm ( Other width can be negotiated) | |

| Front Panel | Material: High grade aluminum alloy (3003,5005, 5754, AA1100) |

| Thickness ≥ 1.0 mm(curtain wall panel's standard); ≥ 0.7 mm(nonstandard) | |

| Core Materials | Material : High grade anticorrosive aluminum honeycomb core material |

| Aluminum foils' thickness: 6mm | |

| Back Panel | Material : High grade aluminum alloy (3003,5005, 5754) |

| Thickness ≥ 0.7 mm(standard) ; ≥ 0.5 mm(standard) | |

| Binder | Two-component high-temperature curing polyurethane adhesive of fuller/hot melt adhesive membrane. |

| Treatment | Roller coating/ Anodized oxidation/ Powder coating/ PVDF coating |

| Color | Plain colored, metallic color, pearl etc.. |

| Density | 5.0-7.5 kg/ m2 |

| Fireproof Performance | A2 (GB8624-2012) |

|